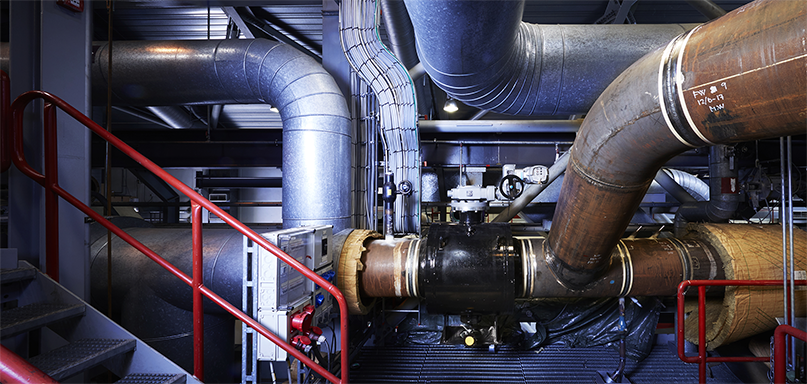

District Energy Station, Helsinore

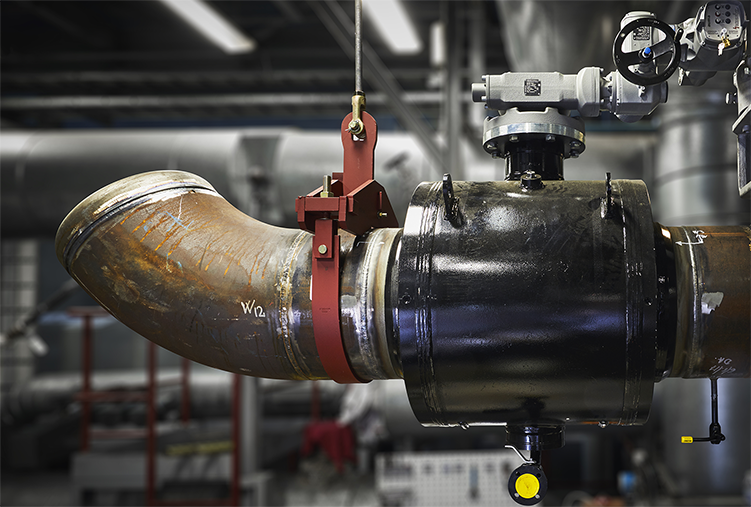

BROEN Ballomax® with double bearing valve ball securing effective shut-off and correct flow.

|

Kronborg Castle – effective control in the 1420s From time immemorial the Kronborg Fortress located just outside Elsinore controlled the ships passing through the Sound and protected the infrastructure and values of the Danish kingdom to ensure that no enemy ships passed through the Sound and that correct tax was paid for passage. Identically the heating supply in Elsinore in 2017 is a central element in today’s infrastructure and must operate optimally to ensure that the large quantities of hot water circulated daily are used, where the heat is required – and not lost en route.

Green transition and renovation Forsyning Helsingør, the local public utilities company in Elsinore, is planning to renovate district heating and make it future-proof. A reliable solution at competitive prices is requested, a solution also supporting the green transition from 2019 – this is both a local target and a national issue. In order to meet this target, the power station is in the process of replacing natural gas as fuel by sustainable wooden chips – and commence a future that is no longer based on fossil fuels. Forsyning Helsingør intends to be one of Denmark’s leading public utilities companies promoting a well-functioning and eco-conscious local society and supplying electricity, water and heating as well as making sure that waste and waste water are handled correctly.

Forsyning Helsingør – the peak load station remains an asset. Today the heat and power station primarily produces electricity and as a secondary, run-off product district heating can be circulated in the district heating system of the town. With an output of 55 MW the existing heat and power station is to remain active as a reliable back-up and peak load station. The boiler of the station is fired by natural gas and produces steam to a steam turbine that in turn produces power. The peak load station will be put into operation if the price of electricity is high and the price of natural gas low – and if electricity prices are favorable and it is operationally sound, heat is also produced to a storage tank holding 16,000m3 – approx. 700 MW. The peak load station is renovated to effectively secure a correct flow, effective shut-off and to optimize the synergy with the new wooden chip plant.

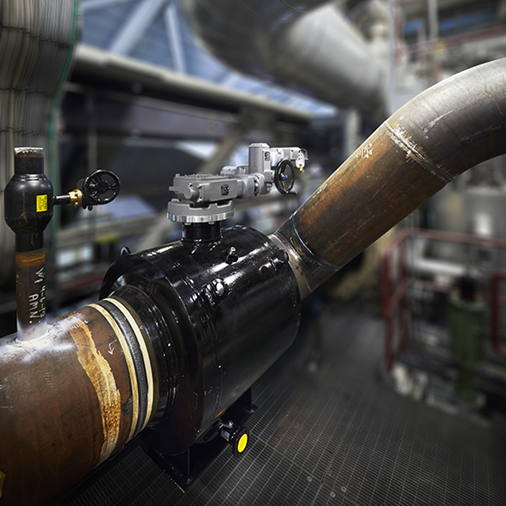

Consequently, in the spring of 2017 Forsyning Helsingør had four new BROEN Ballomax® DN500 Trunnion valves with DBB outlet valves welded into the existing power station (all four valves are 150°C / PN25). Two BROEN Ballomax® valves function as main shut-off valves between the new biomass plant and the combined heat and power station. Two other BROEN Ballomax® valves with AUMA gear function as bypass valves, that can direct the supply pipe water from the biomass plant into the steam boiler for further heating, if the temperature is not sufficiently high, before it is circulated to the users. With a maximum flow capacity of 2,400m3/h, temperatures of up to 120°C and a pressure of up to 25 bar, it is important that the valves function correctly. Forsyning Helsingør has chosen to renovate the combined heat and power station with a sustainable fuel in the form of wooden chips. The existing station will be upgraded to function as a reliable peak load station and the components must also here function safely and optimally. Therefore BROEN Ballomax® valves have been chosen with functionalities providing additional reliability as a non-planned shut-down would be a disaster. Great importance has been attached to buying from a proven supplier, that backs up his product – and that will also be around tomorrow.

BROEN Ballomax® Trunnion with Double Block and Bleed The new valves welded into the station have a special job to do and are so-called Trunnion valves – i.e. double bearing valves which means that the ball is anchored both at the top and at the bottom. This reduces friction and torque considerably, when the valve is activated. Valves fitted with a relief valve - popularly called a ”tell-tale valve” - ensure, that the chamber between the ball and the body can be completely emptied, so that it is possible to ascertain, if the valve closes 100% tightly – hence the name Double Block and Bleed.

BROEN Ballomax® DN50 – Double bearing valve ball with Double Block and Bleed – DBB – outlet under the valve body

|